Greetings from Hajime Matsuoka

In my younger days, I, Hajime Matsuoka, devoted myself to thorough fundamental research, such as the movement of individual soil particles.

This was because I wanted to ascertain the root—the essence—of things.

Discovery of the SMP (Matsuoka-Nakai) Failure Criterion

Among these, I was fortunate to discover the SMP (Matsuoka-Nakai) failure criterion (a failure criterion for soil materials based on the Spatially Mobilized Plane—SMP)—which is a three-dimensional version of the Mohr-Coulomb failure criterion (defined by the cohesion force c and the internal friction angle φ) commonly used by soil and geotechnical engineers.

This SMP criterion clearly aligns with the Tresca and Mises criteria for metallic materials.

That is,

- The two-dimensional Mohr-Coulomb criterion for granular materials like sand

- The three-dimensional SMP (Matsuoka-Nakai) criterion for granular materials like sand

- The two-dimensional Tresca criterion for metallic materials

- The three-dimensional Mises criterion for metallic materials

The interrelationships between these four criteria are extremely beautiful and simple, both mathematically and physically, leaving absolutely no room for anything else.

This historic discovery has been highly praised worldwide.

(However, there is a difference between compressive stress for granular materials and tensile stress for metal materials.)

Step 1:

Deformation and failure of granular materials like sand are governed by interparticle friction (τ/σ, the ratio of shear stress τ to normal stress σ).

The plane with the largest τ/σ is the point where a line from the origin touches Mohr’s stress circle, and is therefore a plane that is more perpendicular than 45° plane.

It is well known that the slip plane (failure plane) of soil is{45° + φ/2}plane (φ: angle of internal friction at failure).

Step 2:

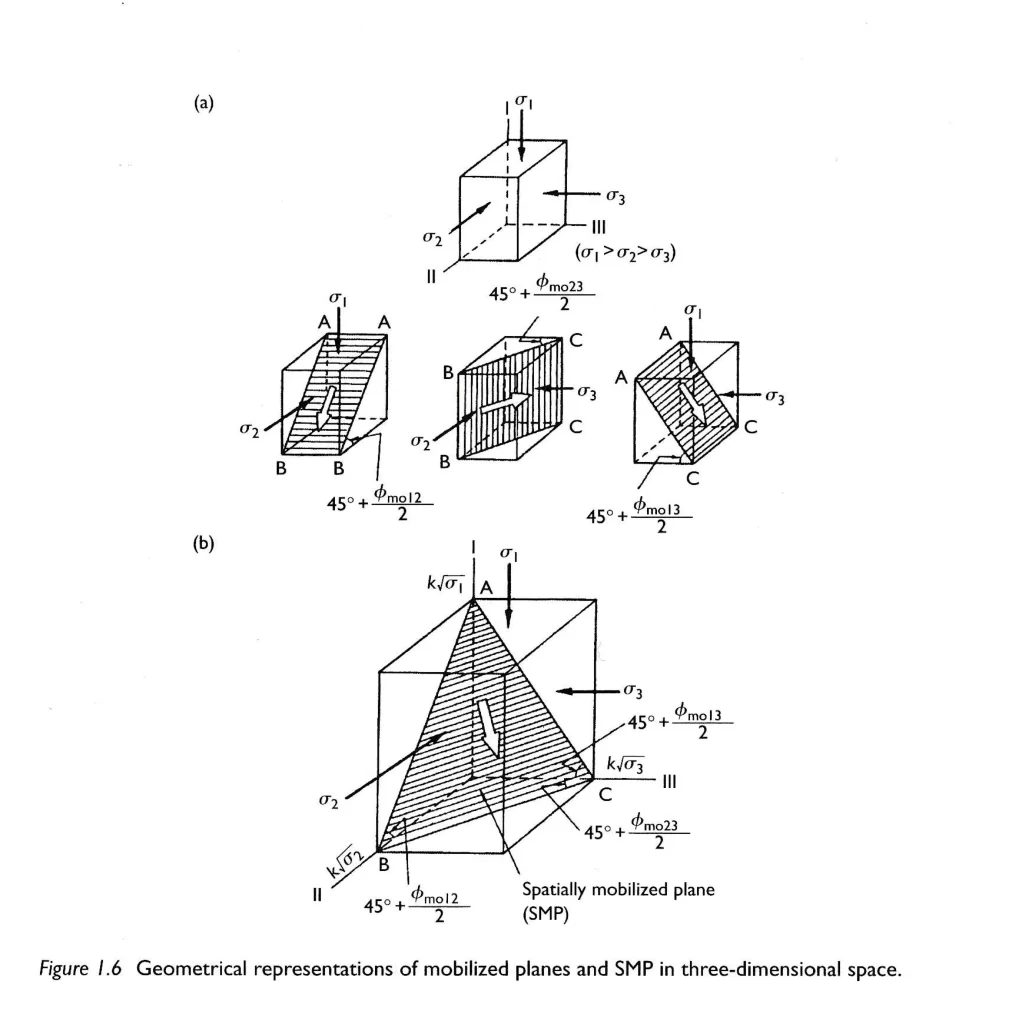

How should we consider the above discussion under three-dimensional stress conditions?

When three different principal stresses act on soil elements, i.e., the maximum principal stress σ1, the intermediate principal stress σ2, and the minimum principal stress σ3(σ1 > σ2 > σ3), I considered not only a two-dimensional mobilized plane between the maximum principal stress σ1 and the minimum principal stress σ3 (the AC plane in the figure below), but also a two-dimensional mobilized plane between the maximum principal stress σ1and the intermediate principal stress σ2(the AB plane in the figure below) and a two-dimensional mobilized plane between the intermediate principal stress σ2 and the minimum principal stress σ3 (the BC plane in the figure below).

A mobilized plane is a plane along which soil particles slide, eventually leading to the sliding plane (failure plane).

In my doctoral thesis (Deformation Characteristics of Soil, August 1973, Kyoto University), I successfully expressed the stress-strain relationship under the three principal stresses as a superposition of strains generated on these three two-dimensional mobilized planes (collectively named Compositely Mobilized Planes, or CMP).

(See Matsuoka, “A New Approach to Geotechnical Engineering,” Kyoto University Press, 2003, pp. 7-15.)

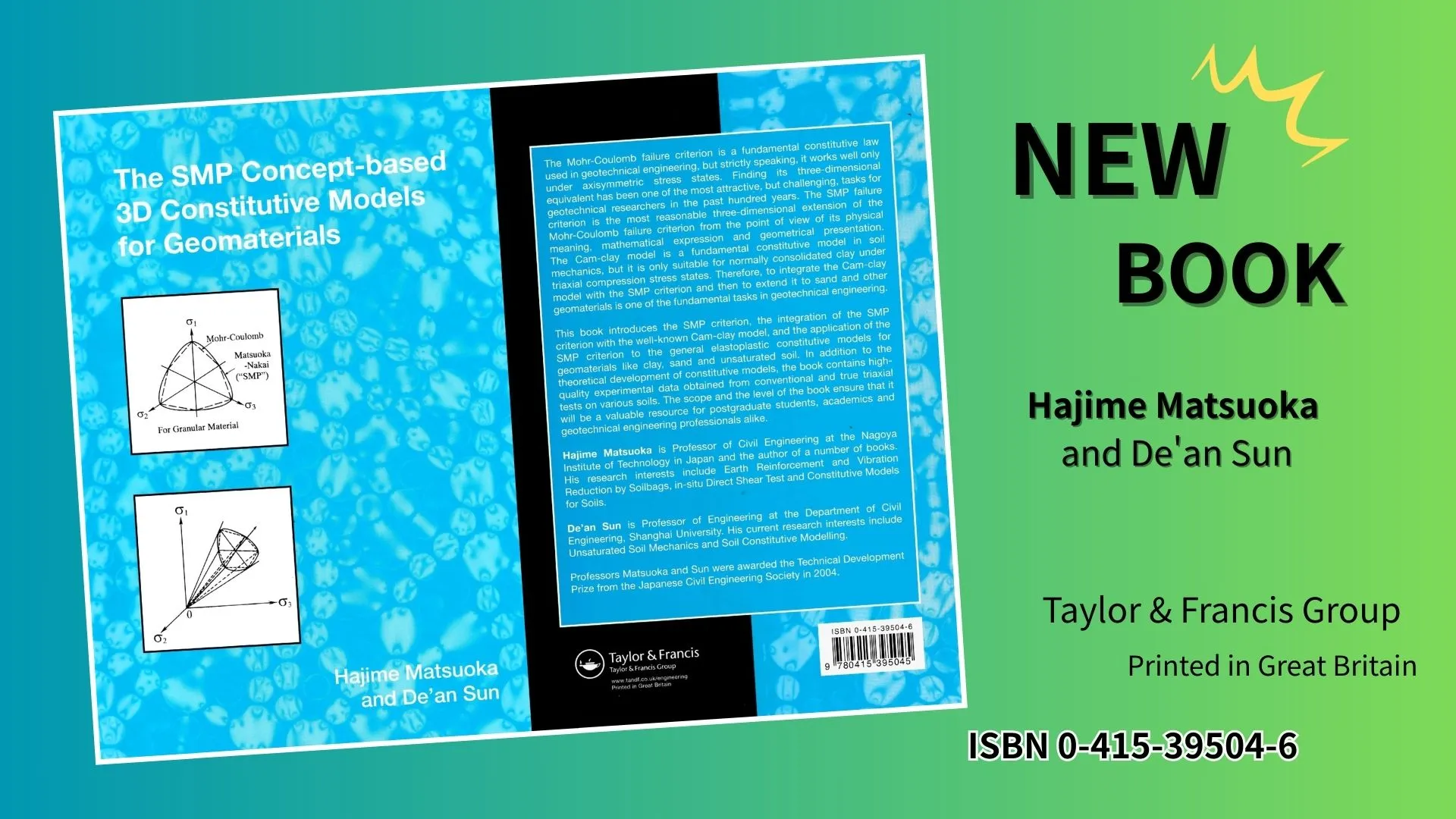

(See Matsuoka & Sun,”The SMP Concept-based 3D Constitutive Models for Geomaterials”,Taylor & Francis,2006,pp.1-9 in English)

Step 3:

Looking at the three two-dimensional mobilized planes AB, BC, and AC in the figure below (Figure 1.6(a)), a three-dimensional plane ABC(Figure 1.6(b)) began to emerge.

This is the Spatially Mobilized Plane (SMP).

By organizing the ratio of shear stress τSMP to normal stress σSMP on this SMP (τSMP/σSMP), shear strain, and normal strain, I jumped for joy when the results of a triaxial compression test (σ1 > σ2 = σ3), a triaxial extension test (σ1 = σ2 > σ3), and three-principal stress tests(σ1 > σ2 > σ3) for the same sand (same density) all fell on a single curve.

It was when my graduate student, Teruo Nakai, completed his master’s thesis.

The SMP (Matsuoka-Nakai) failure criterion states that a granular material like sand will fail when τSMP/σSMP = a certain value.

This is a three-dimensional version of the commonly used Mohr-Coulomb criterion.

(See Matsuoka & Sun,”The SMP Concept-based 3D Constitutive Models for Geomaterials”,Taylor & Francis,2006,pp.9-14 in English)

Step 4:

I was casually looking at the two-dimensional failure criterion for metals, the Tresca criterion (1868), and the three-dimensional failure criterion for metals, the Mises criterion (1913), and I noticed something interesting.

While metallic materials, which are connected by a crystalline structure, are expressed on the coordinate axis of tensile stress, while granular materials, which consist of discrete particles, are expressed on the coordinate axis of compressive stress, there was a beautiful correspondence between the form of the failure criterion equation, the stress points on Mohr’s stress circle, and the shape of the failure plane under three-dimensional stress.

The fundamental difference between the two materials is that metallic materials fail at the maximum shear stress τmax, while granular materials fail at the maximum shear stress/normal stress ratio (τ/σ)max.

For details on the beautiful interrelationship between the two-dimensional failure criterion for metallic materials (Tresca’s criterion (1868)) and the three-dimensional failure criterion (Mises’s criterion (1913)), and the two-dimensional failure criterion for granular materials (Mohr’s (1882) and Coulomb’s (1773) criterion) and the three-dimensional failure criterion (Matsuoka and Nakai’s (SMP) criterion (1974)), please see the above-mentioned references: “New Approaches in Geotechnical Engineering,” pp. 22-29, and “Soil Mechanics” by Matsuoka, Morikita Publishing Co., Ltd., 1999, pp. 143-149.”

(See Matsuoka & Sun,”The SMP Concept-based 3D Constitutive Models for Geomaterials”,Taylor & Francis,2006,pp.14-20 in English)

Step 5:

I realized that if we can understand the extremes of truly frictional materials like granular materials with no bonds between particles (materials with cohesion c = 0, φ>0) and truly cohesive materials like metals with strong cohesion due to their crystalline structure (materials with internal friction angle φ = 0, c>0), all materials lie somewhere in between and are easy for humans to handle.

Therefore, we have considered a failure criterion for intermediate materials between metals and granular materials.

For details, please see the above-mentioned paper: A New Approach in Geotechnical Engineering, pp.30-35.

(See Matsuoka & Sun,”The SMP Concept-based 3D Constitutive Models for Geomaterials”,Taylor & Francis,2006,pp.20-24 in English)

Please see the page below for details.

Changing Research Direction

As I approached my 50th birthday, I had the opportunity to reflect on my research with a sense of prayer.

I began to realize that, since I had been able to do what I loved with taxpayers’ money, I should consider doing something that would be useful in my final 10 years or so.

I conducted model experiments targeting the application of soil mechanics, such as earth pressure, bearing capacity, and slope stability.

From these experiments, I was delighted to develop the “Soil Bag (D-Box) Method,” a high-standard sandbag construction method that mechanically elucidates the wisdom of our ancestors, the “sandbag,” and actively utilizes what was previously a temporary material as a permanent construction material.

*The D-Box is a product developed by Futoshi Nomoto, President of Metry Technical Research Institute, Inc., since 2006, based on the theory, effectiveness, construction track record, and guidance of the soil bag construction method developed by Matsuoka et al. This method takes advantage of the diverse benefits of soil bags, such as ground reinforcement and mitigation of liquefaction, vibration, and seismic motion, and adapts them to actual public works projects.

Soil Bag (D-Box) Construction Method

The soil bag (D-Box) construction method offers the following benefits:

- Increased bearing capacity and subsidence prevention:

- The filtering effect of the sandbag mesh encourages local consolidation and strengthening of the soft ground directly below the sandbag.

- Liquidity reduction:

- The filtering effect of the sandbag mesh drains water, reducing water pressure and preventing sand outflow.

- Traffic vibration and seismic motion reduction:

- The loose and flexible properties of the sandbag stacks help reduce traffic vibration, mechanical vibration, and seismic motion.

- Frost heave prevention:

- Placing large crushed stone inside the sandbags prevents capillary rise of water.

The soil bag construction method, which achieves many benefits with one stone, is an incredible method that transcends human ingenuity.

This construction method has currently been used in over 5,000 installations, including overseas.

Going forward, we would like to make every effort to spread this method not only throughout Japan but also around the world, including developing countries.

We ask for your continued cooperation and support.

Academic background

| March 1966 | Kyoto University, Faculty of Engineering, Department of Civil Engineering |

| March 1968 | Kyoto University Graduate School, Graduate School of Engineering, Department of Civil Engineering, Master’s program |

| March 1971 | Kyoto University Graduate School, Graduate School of Engineering, Department of Civil Engineering, Doctoral course credit acquisition |

Degree

| January 1974 | Doctor of Engineering (Kyoto University) ”DEFORMATION CHARACTERISTICS OF SOIL” |

Work history

| April 1971 | Research Assistant, Disaster Prevention Research Institute, Kyoto University |

| April 1973 | Assistant Professor, Disaster Prevention Research Institute, Kyoto University |

| April 1976 | Associate Professor, Faculty of Engineering, Nagoya Institute of Technology |

| September 1976 | Overseas training at the Norwegian Geotechnical Institute sponsored by the Norwegian Gavernment(until October 1977) |

| January 1986 | As a long-term overseas researcher sponsored by the Japanese Ministry of Education, Business trip to University of Sydney in Australia and University of Oxford in UK (until November 1986). |

| October 1987 | Professor, Faculty of Engineering, Nagoya Institute of Technology |

| April 2006 | Professor Emeritus, Nagoya Institute of Technology (to date) |

Affiliated academic society

- Geotechnical Society

- Japan Society of Civil Engineers(currently retired)

- Architectural Institute of Japan(currently retired)

List of publications

“Fundamentals of design and construction of the D-Box construction method ~Strengthening soil cultivation and reducing liquefaction, vibration, and seismic motion~” (written in Japanese)

October 2020 Morikita Publishing Co., Ltd. (co-authored with Haruyuki Yamamoto and Futoshi Nomoto)

「The SMP Concept-based 3D Constitutive Models for Geomaterials」

2006 Taylor & Francis (formerly A. A. Balkema) (co-authored with D. A. Sun)

「A New Earth Reinforcement Method using Soilbags」

2006 Taylor & Francis (Formerly A. A. Balkema) Group (Co-authored with S. H. Liu)

“New approach to geotechnical engineering – constitutive equations, testing methods, and reinforcement methods” (written in Japanese)

2003 Kyoto University Academic Press

“Soil Mechanics (Basic Civil Engineering Series 15)” (written in Japanese)

1999 Published by Morikita Publishing Co., Ltd.

List of papers

*Introducing some of the over 100 papers related to the “Soil bag construction method.”

「現代版土のう工法としてのD・BOX工法と その「一石”多”鳥」効果 <上><下>」

“D-BOX method as a modern sandbag construction method and its “one stone, many birds” effect ”

From an article in the quarterly civil engineering cost information (January and April 2011 issues) published by the Construction Price Research Institute.

「現代版土のう工法としてのD・BOX工法と その局所圧密効果および振動低減効果」

“D-BOX method as a modern soil bag construction method and its local consolidation effect and vibration reduction effect”

Geosynthetics Proceedings Posted December 4, 2010

“Method for countering ground environmental vibration using soil bags”

Seminar on soil environmental vibration countermeasures, Japan Society of Geotechnical Engineers, May 18, 2010

“Local consolidation/strengthening method for ultra-soft ground using soil bags”

Proceedings of the 43rd Geotechnical Research Conference (Hiroshima) July 2008

“Example of road construction on swamp land using high-standard interlocking soil bag construction method”

43rd Geotechnical Research Conference Lecture Collection (Hiroshima) July 2008

「超軟弱地盤(沼地)対策のための高規格連結土のう工法 - 国道125号線(埼玉県)道路工事」

“High-standard interlocking soil bag construction method for countermeasures against ultra-soft ground (swamps) – National Route 125 (Saitama Prefecture) road construction”

Foundation Engineering Vol.36, No.4 April 2008 issue, pp.71-75

Awards

| 1974 | Young Researcher Paper Award, Geotechnical Society |

| 1986 | Outstanding Research Contribution Award, Geotechnical Society |

| 1999 | Geotechnical Society of Japan Merit Award |

| 2003 | Technology Development Award (In-situ Shear Test Method), Japan Society of Civil Engineers |

| 2004 | Japan Society of Civil Engineers Technology Development Award (High-standard sandbag construction method “Soil Bag Construction Method”) |

social activities

| 1973 | Japan Geotechnical Society Kansai Branch Secretary |

| 1976 | Japan Geotechnical Society Chubu Branch Secretary |

| 1980 | Japan Geotechnical Society Paper Report Editorial Committee Member |

| 1986 | Japan Society of Civil Engineers Chubu Branch Secretary |

| 1990 | Geotechnical Society Director |

| 1992 | Japan Geotechnical Society Chubu Branch Deputy Chief |

| 1994 | Japan Geotechnical Society Chubu Branch Chief |

| 1996 | Japan Society of Civil Engineers Chubu Branch Commercial Councilor |

| 2004 | Japan Society of Civil Engineers Award Committee |

Related articles

Click here for “Overview of a book ”SMP Concept-based 3D Constitutive Models for Geomaterials””

Click here for “Overview of a book ”A New Earth Reinforcement Method using Soilbags””

Click here for “Soilbag theory ~Basics of design and construction of the D-Box construction method~”